Burnished Face

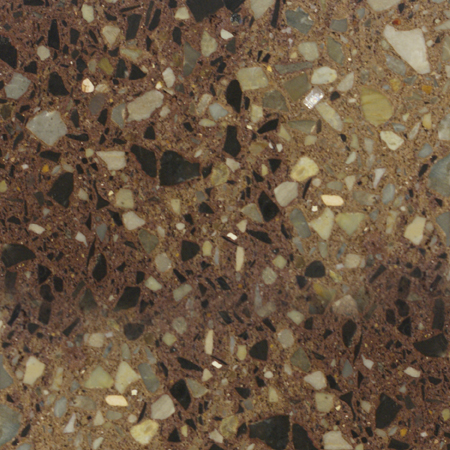

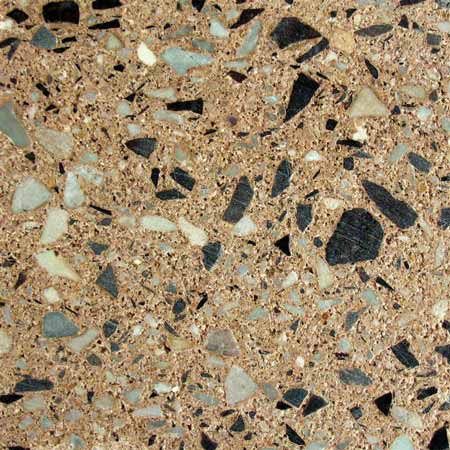

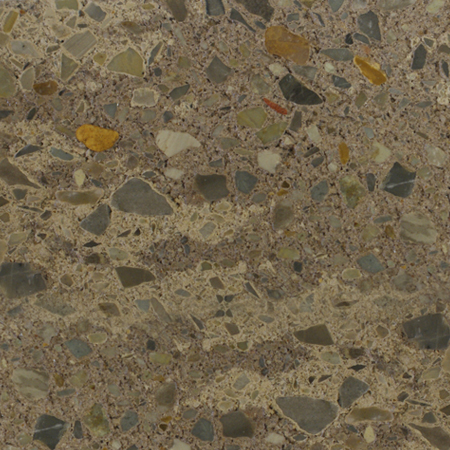

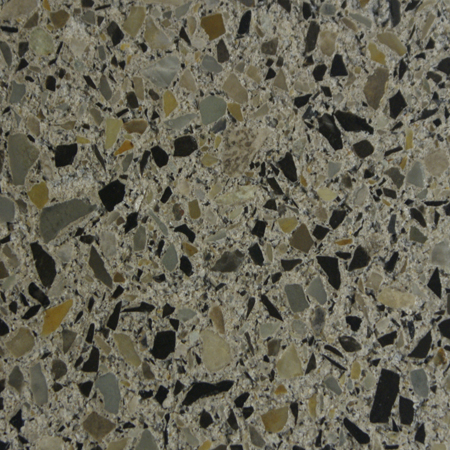

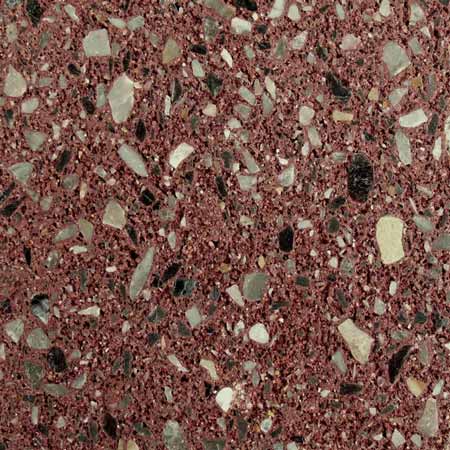

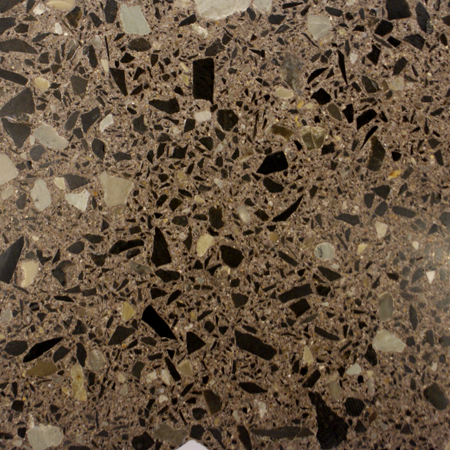

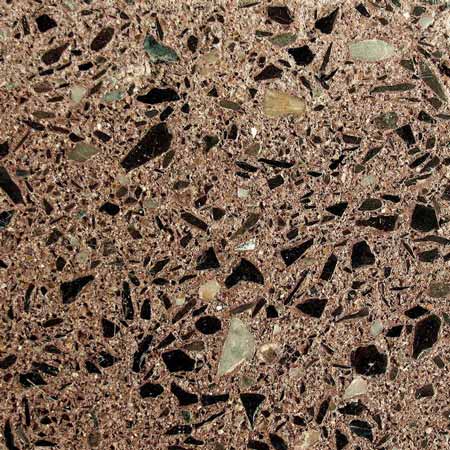

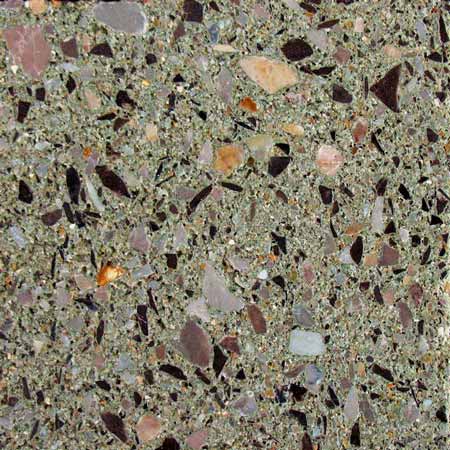

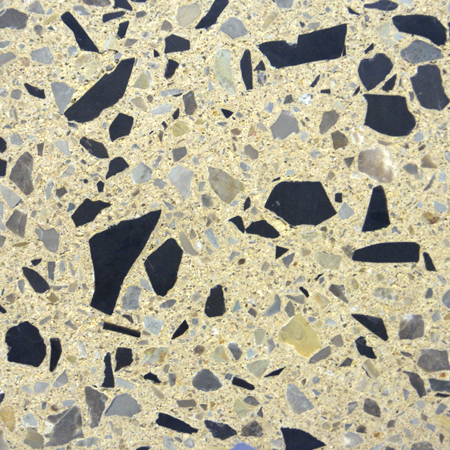

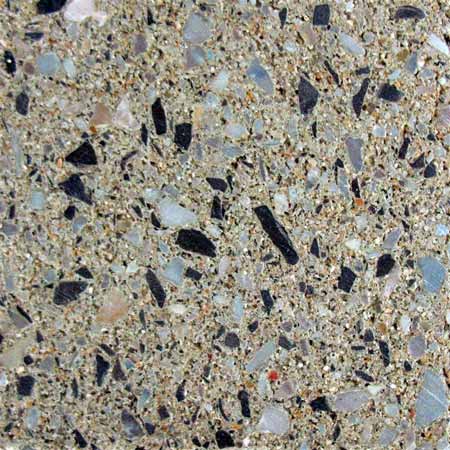

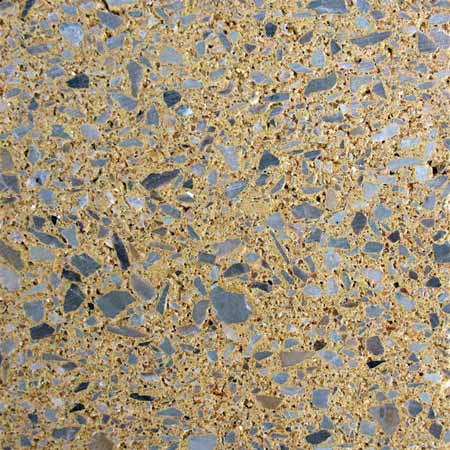

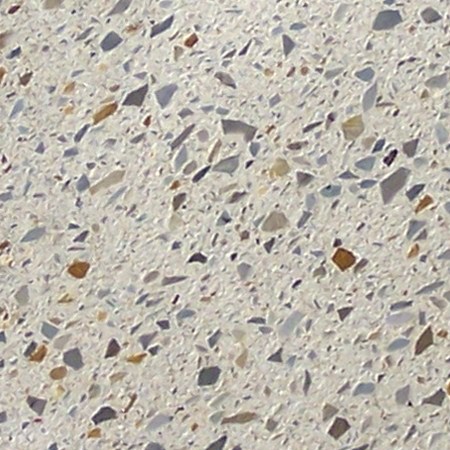

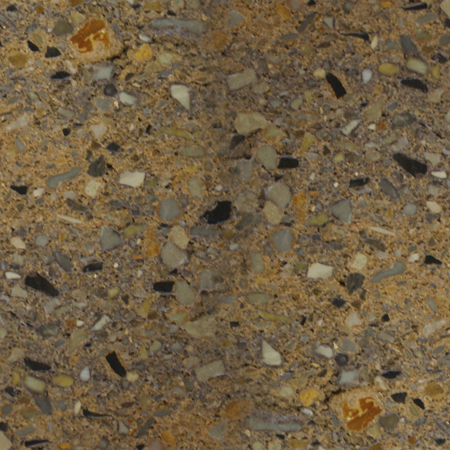

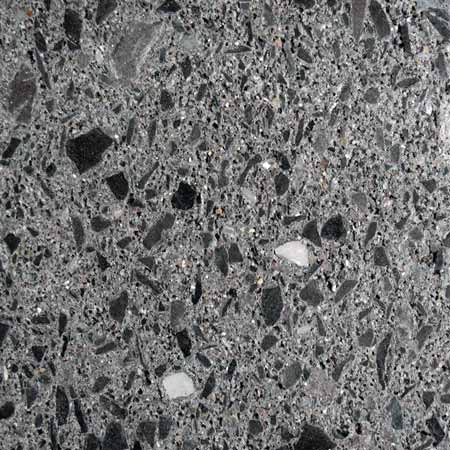

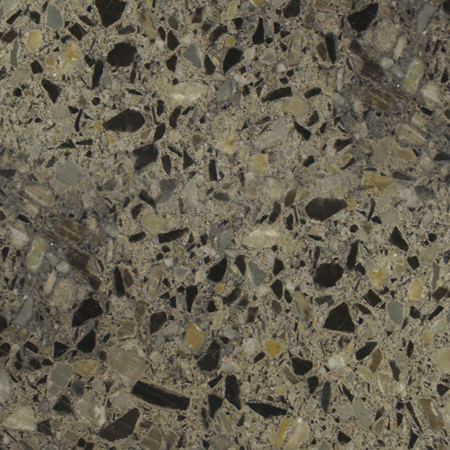

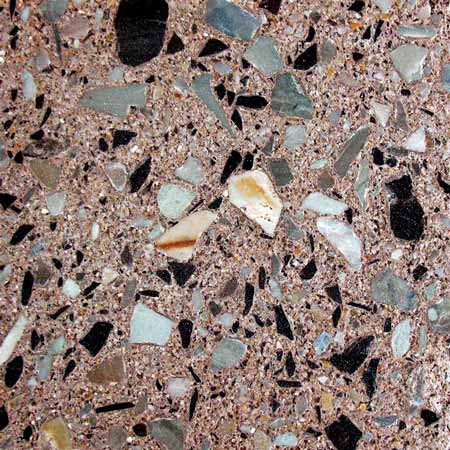

EXPRESS THE NATURAL BEAUTY OF POLISHED STONE AGGREGATE

Nettleton Concrete, Inc. manufactures custom designed, high quality, architectural concrete masonry units with faces that are burnished to expose carefully selected and blended aggregates that are obtained from various quarries and manufacturing facilities throughout the South Central United States. These burnished concrete masonry units are custom blended, colored, and processed with state-of-the-art grinding, polishing, splitting, and various other related equipment. Nettleton Concrete Burnished Masonry Units offer a beautiful and durable alternative to standard concrete masonry. Burnished Units are uniquely processed on one or more surfaces to expose the natural aggregates and create a desirable, polished appearance. Burnished Units will enhance any project with the aesthetics and natural beauty of mined aggregates at a fraction of the cost of polished stone. Nettleton Concrete Burnished Units are manufactured under strict standards while quality control procedures ensure a consistent product of the highest quality.

CREATE A MASTERPIECE IN MASONRY

Burnished Units can be produced in single color or two-tone variegated colors enabling the designer to select expressive color combinations that enhance the project’s architectural style. Colors in Nettleton Concrete Burnished Units are not only on the surface, but blended throughout the entirety of the block. While giving the advantages of standard units, Nettleton Concrete Burnished Units provide a stylish alternative for either interior or exterior load-bearing applications. Stylish and Adaptable, Nettleton Concrete Burnished Units are available in a variety of sizes and specialty finishes such as scoring, bullnosing, and chamfering.

MANUFACTURED TO ENDURE

Integral water repellent is added to each unit to help avoid efflorescence and slow the aging process by preventing water penetration. A jobsite-applied coat of sealer not only enriches the color and appearance of the block, but provides added moisture protection for the block and mortar joints in the finished wall. When a water repellent mortar is used, the entire wall is capable of repelling water and providing lasting beauty.

Product Information

Shape Guide Section

800-382-2462

800-382-2462 2318 Moore Road Jonesboro, AR 72401

2318 Moore Road Jonesboro, AR 72401 sales@nettletons.com

sales@nettletons.com Mon - Thurs 7am - 5pm

Mon - Thurs 7am - 5pm